Help is here

Top 10 Tips for Choosing the Best Tire Air Valve for Your Vehicle

When it comes to maintaining vehicle safety and performance, often overlooked components can have a significant impact. One such component is the tire air valve, a small yet crucial part that ensures your tires remain properly inflated. Renowned tire expert Dr. Emily Carter emphasizes, "Choosing the right tire air valve is essential not only for optimal tire function but also for overall vehicle safety." With several options available, selecting the best tire air valve can be daunting for many vehicle owners.

Understanding the factors influencing tire air valve selection can help you make an informed decision. Whether you are replacing worn-out valves or upgrading to enhance performance, knowing what to look for can save you from potential issues down the road. In this guide, we will explore the top 10 tips for choosing the best tire air valve for your vehicle, equipping you with the knowledge needed to make the right choice for your specific needs and ensuring a safer driving experience.

Understanding the Functionality of Tire Air Valves for Vehicles

Tire air valves, often overlooked in vehicle maintenance, play a crucial role in ensuring optimal tire performance and safety. These components allow air to enter and exit the tire, which is essential for maintaining proper inflation pressure. According to industry research published by the Tire and Rim Association, maintaining proper tire pressure can enhance fuel efficiency by up to 3%, while also improving the overall lifespan of the tires. An improperly functioning valve can lead to air leaks, which may result in under-inflation, affecting handling and fuel economy.

Understanding the functionality of tire air valves can also lead to safer driving experiences. Data from the National Highway Traffic Safety Administration indicates that under-inflated tires are responsible for approximately 10% of all tire-related crashes. A well-maintained valve prevents air loss and maintains the necessary pressure, thus contributing to better traction and reduced stopping distances. Moreover, regular inspection of the valve for signs of wear or damage can mitigate issues before they contribute to compromised safety, further affirming the importance of selecting the right type of air valve for each vehicle's specific needs.

Top 10 Factors Influencing Tire Air Valve Selection

Identifying the Right Valve Type for Your Vehicle's Tire System

When it comes to selecting the right tire air valve for your vehicle, understanding the specific type that fits your tire system is crucial. There are mainly two types of tire valves: Schrader and Presta. Schrader valves are commonly used in the majority of vehicles, including cars and trucks, due to their ease of use and compatibility with most air pumps. They are characterized by a wider barrel and a spring-loaded pin that opens the valve when pressed. Presta valves, on the other hand, are typically found in bicycles and high-performance vehicles, featuring a narrower profile and a locking mechanism that helps maintain tire pressure during high speeds.

In addition to knowing the type of valve, it's important to consider how the valve fits into the tire rim. Ensure that the length of the valve stem is appropriate for your rim depth, as too long or too short can affect inflation and deflation processes. Also, take note of the material and construction of the valve. Rubber valves are common and economical, but metal valves are more durable and offer better longevity, especially in harsh conditions. By assessing these elements, vehicle owners can confidently choose the best air valve that suits their tire system, ensuring efficient performance and safety on the road.

Assessing Compatibility: Tire Size and Valve Specifications

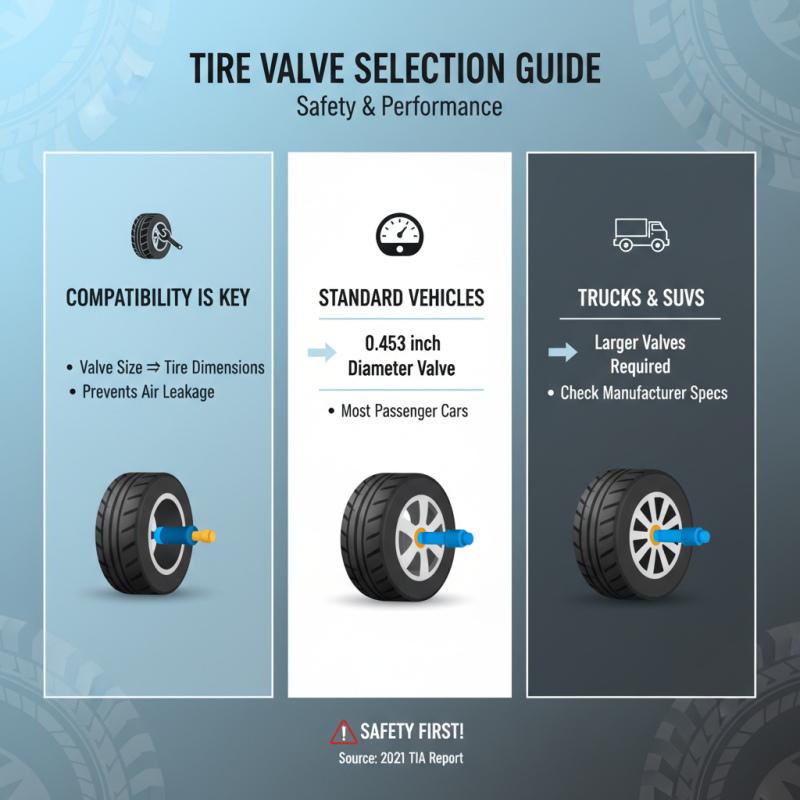

When selecting the best tire air valve for your vehicle, understanding the compatibility of tire size and valve specifications is paramount. According to a 2021 report by the Tire Industry Association, improper valve selection can lead to air leakage, which can ultimately compromise vehicle safety and performance. This emphasizes the importance of matching the valve size with the tire dimensions—most standard passenger vehicles use a valve size of 0.453 inches in diameter, but certain vehicles, especially trucks and SUVs, may require larger valves.

In addition to size, the specifications for the valve's construction materials should be taken into account. A study by the Automotive Research Institute indicated that valves made from high-quality materials, such as brass or high-grade rubber, show increased durability and resistance to environmental factors, prolonging their lifespan. Ensuring that the air valve is compatible not only with the tire's physical dimensions but also with the specific pressure requirements of the vehicle can lead to enhanced performance and better fuel efficiency. Therefore, it's critical to consult tire specifications and refer to manufacturer guidelines to ensure a proper fit and optimal functionality.

Materials and Durability: Key Factors in Valve Selection

When selecting a tire air valve for your vehicle, the materials used in its construction and overall durability are crucial factors to consider. Valves made from high-quality materials, such as brass or high-grade synthetic rubber, offer enhanced resistance to wear, corrosion, and extreme temperatures. These materials ensure that the valve can withstand daily driving conditions and contribute to prolonged tire life. The durability of the valve is directly related to maintaining optimal tire pressure, which, in turn, impacts vehicle performance and safety.

Tip 1: Inspect the valve's construction material to ensure it aligns with your driving conditions. A valve designed for high-temperature resistance is essential if you frequently drive in hot climates. Additionally, opting for a valve with a protective coating can further enhance durability, preventing degradation over time.

Tip 2: Pay attention to the valve's design. A well-designed valve not only facilitates easier inflation and deflation but also minimizes the risk of leaks. Look for features like dust caps and seals that can keep contaminants out, ensuring that your valve remains functional and free from debris.

Taking these considerations into account will help you choose a tire air valve that not only meets your vehicle's needs but also enhances safety and efficiency on the road.

Installation: Tips for Properly Fitting Tire Air Valves

When it comes to installing tire air valves, proper fitting is crucial for ensuring optimal performance and longevity of your vehicle's tires. According to a report from the Tire Industry Association, improper installation can lead to air loss, which is one of the primary causes of tire blowouts. To prevent such issues, make sure that the valve stem is compatible with your tire and wheel assembly. The right fit not only prevents air leaks but also enhances safety while driving.

Before installation, it is advisable to check the condition of the valve stems. A study published by the Rubber Manufacturers Association indicates that nearly 30% of tire failures are attributed to worn or defective valve stems. When fitting new valves, ensure that they are cleaned and free from debris. Additionally, using a torque wrench to tighten the valve nut to the manufacturer-recommended specifications can prevent air loss and preserve the structural integrity of the valve. By paying attention to these details and adhering to proper installation techniques, you can significantly improve the reliability and performance of your tire system.

Related Posts

-

Understanding TPMS Systems: How Tire Pressure Monitoring Can Save You Money and Enhance Safety

-

Top Tips for TPMS Service in 2025 You Need to Know Today

-

Top 10 Benefits of Tire Pressure Sensors for Safe Driving

-

Top 5 Tire Valve Sensors You Should Consider for Optimal Performance

-

Understanding Tire TPMS: How Your Car's Pressure Monitoring System Enhances Safety and Efficiency

-

Unlocking the Secrets of Tire Fluid for Enhanced Vehicle Performance and Safety